“Fun, versatile & practical.” That’s how the owner of Fearless Bikes describes the bikes that they sell. Fearless Bikes are based on the south coast in the UK and produce a range of frames blending the best of gravel, off-road touring, all terrain and monstercross. We chatted with the company’s founder Tim to get some insight into what makes them tick and about his love of creating “out of bounds” bikes.

Gravel Union - Can you introduce yourself please?

Tim - Hi, I’m Tim, the owner/operator of Fearless bikes.

GU - Before we get onto Fearless Bikes, can you tell us a little about your background as a rider?

Tim - I got into cycling as a youth during the mountain bike boom of the late 80s/early 90s. MTBs were the cool thing to have, were fashionable but I actually put a lot of miles on mine, both for fun and also transportation. A lot of friends dropped out of cycling when it wasn’t flavour of the month, but I stuck with it. I got into road touring in the 2000s and did a few long tours including a trip across the US. I was still riding cross country on a mountain bike at home though and I still think of myself as a cross-country rider even though I don’t currently have an MTB built up.

GU - When and why did you start Fearless?

Tim - There’s no single answer as to why but I do remember being bored with my lot and wanting to do something different. I tried a few things but none of them stuck. Around that time I came to the realisation that I had too many bikes and started paring down my collection. I owned a touring bike with big tyre clearances and a 3x9 drivetrain which I rode off-road instead of a mountain bike for a while. It was a fully-fledged loaded touring frame, so it was designed to ride well when loaded up, but a little too stiff when not. It was a lot of fun though. I bought a steel cyclocross frameset with a view to it being the ‘one bike’ but the frame was a little too flexy for my liking and I wasn’t that happy with the geo which got me thinking.

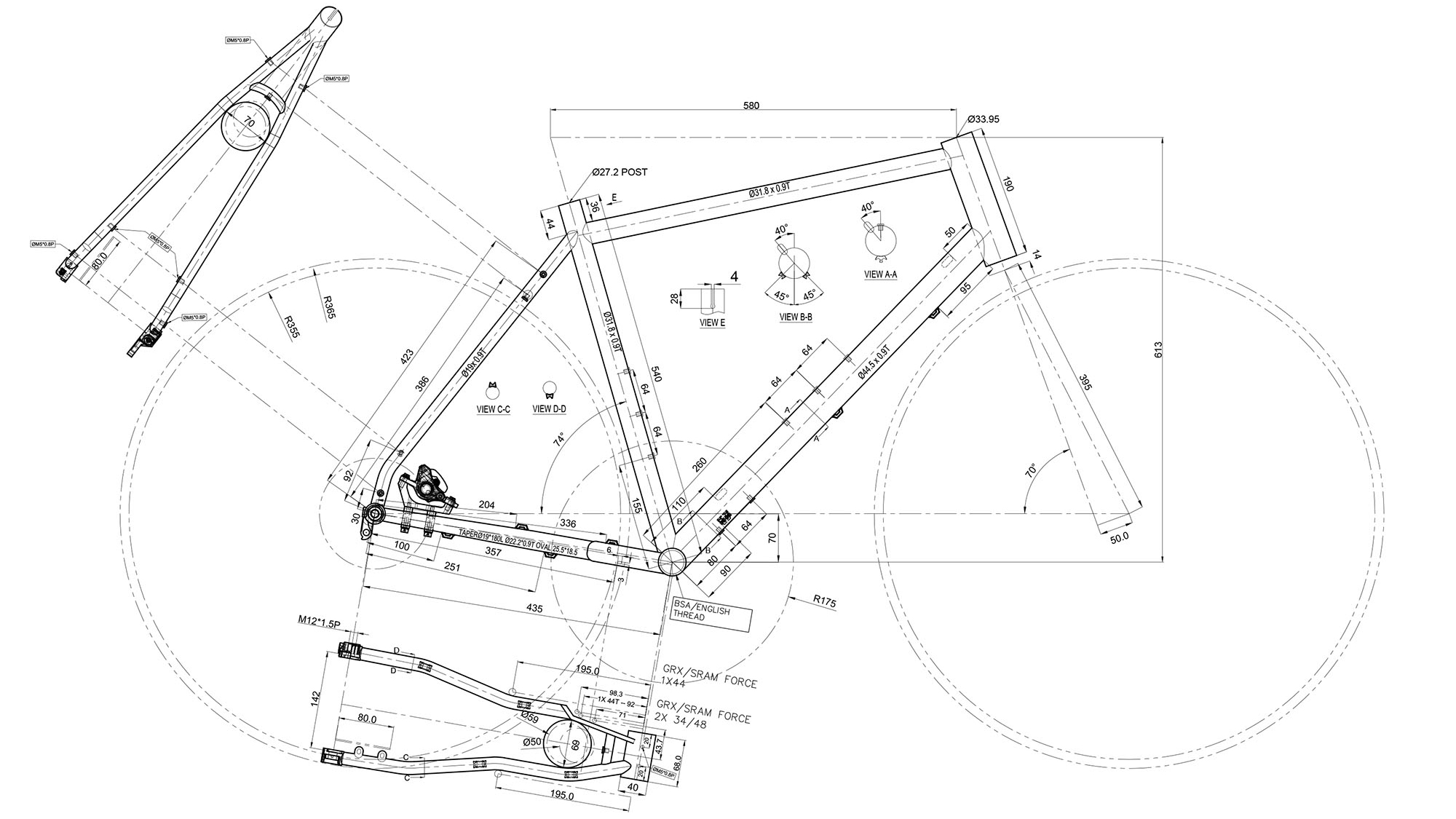

At the time the term gravel bike wasn’t common parlance here in the UK, though I’d read about the race scene in the US. I just wanted a drop bar bike with big tyres that I could tour, ride off-road and commute on, so I didn’t see a connection. I suppose sometimes in the framing of things, the marketing gets in the way. I came into a little inheritance after my father passed away in 2015, which was enough to get a run of framesets made. I’d followed a few people who had started their own bike brands, so I started researching and contacting a few people to see if starting a brand was feasible. I’d studied technical drawing and my late father was a draughtsman, so I’d grown up around engineering drawings. That side of it wasn’t daunting. It took a while to get things off the ground. I took delivery of the first Vulture framesets just after Christmas 2017.

GU - Can you give us an overview of the two different frames that you offer?

Tim - The Mk 1 Warlock was what I thought of as a ‘rowdy' gravel bike - slightly slacker than normal gravel bike geometry, took largish tyres and handled well off-road but had good road performance. It was great for proper mixed-terrain touring. The Warlock is no longer being offered but it’ll be back. I have lots of ideas for the Mk2 but need to shape them into something tangible.

I call the Vulture Titanium an “out-of-bounds” bike though it’s actually a great all-rounder, capable of doing lots of different things. Performs off-road, it’s lightweight, has stable geometry so it’s great for backpacking and light touring. There’s a steel version due early next year albeit with a couple of changes over the titanium version. It’s still a lightweight frameset despite being steel, whereas the Warlock was more of a bruiser.

GU - Where did the inspiration for the names of your frames come from?

Tim - The Vulture came from a risky day on the road from Needles on my way to Los Angeles and attempting to make it to Barstow before sunset. It was August in the Mojave Desert, so too hot to be on the road all day and I was suffering from heat exhaustion by mid-afternoon. I’d presumed I was thoroughly acclimatised after cycling all the way from Chicago, as it had been in the 30s Celsius for most of the trip, but the Mojave was a step beyond. Making presumptions can be dangerous when touring. I was the only thing on the road and some Vultures were circling overhead, following me from Amboy. Having a gang of raptors wanting you to fail leaves an impression. Anyway, I made a decision to try and name the bikes after living creatures either real or fictional. I like to think of Fearless’ bikes as having character. The Mk1 Vulture was fairly light for a steel frameset, so naming it after a bird, albeit a pretty vicious one made sense. The Warlock name came about as I was looking at short wheelbase off-road vehicles with a lot of them being military - Land Rovers, Jeeps and the like. Calling it the Warlock tied the two themes together. I don’t attempt to be too clever or cryptic with the names, though hopefully they’ll continue to be thematic.

GU - Both the Warlock and the Vulture Titanium have clearance for big tyres – the Vulture Titanium can run up to 29 x 2.2”. What made you go for such generous clearances (and we ask that as big fans of #monstercross bikes…)

Tim - To be honest, I don’t really think of the Vulture Ti as a monster cross, but more of a natural progression of the gravel bike, a do-it-all bike, though I’m happy with the #monstercross label. The majority of Fearless’ customers are fairly experienced riders – a lot of them have owned a wide range of bikes so understand the benefits of bigger tyres. Also, larger tyre clearances means a wider selection of tread patterns - you’re not locked into just 700c gravel & all-road tyres. This makes the new iteration of the Vulture a true all-rounder, a proper all-terrain bike.

GU - You’re based on the south coast in the UK. Does your local gravel riding (with short, sharp climbs, lots of woodland singletrack and chalk ridgelines) affect the design of the frames that you offer?

Tim - There’s also a lot of rolling downland and some of the climbs aren’t that short. It’s not the Peak District, but there’s some challenging riding to be had. The framesets I design have to be wide in scope and a lot of customers ride in locations a lot more challenging than what’s on offer around here. Riding drop bars keeps it fresh & interesting for me, though a standard gravel bike with 40mm tyres and tall gearing won’t get you over everything. To be honest I don’t see that many gravel bikes on the hills around here - it’s mostly people riding XC on progressive geo MTBs with more suspension than they need, so they’re over-biked for most of the situations they’ll encounter.

GU - What kind of quality control checks do you make to your frames before they get shipped out to your customers?

Tim - Generally, most of the QC stuff is done pre-production and the prototyping stage is there to fix problems before they occur. It functions in part as a trial run. The factories I use aren’t the cheapest, but the quality is superb - they have reputations to keep and are conscientious. The really important post-weld stuff like checking frame, BB and headtube alignment are done at the factory these days. One thing that all bike brands have to deal with is paint-related issues - either too little or overspray. The thick powder coat that we use means contact points need to be masked so components interface correctly to the frame as paint build-up can occur in these areas. We had an issue on the new steel prototype with the rear axle thread binding, which turned out it was powder coat build-up inside the non-drive side dropout misaligning the rear axle, so that area will masked for production. I’ll be chasing the rack & mudguard eyelets and fitting stainless bolts as I already do with the bottle & Anything Cage mounts. I was hesitant to do so initially as not everyone fits a rack and mudguards, but I listen to what customers say and make changes where I can.

GU – Quick-fire question – 700c/29” or 650B and why?

Tim - I’ve been more of a 650B person in recent years, though only with wider tyres. You really need to be running bigger tyres at low pressures to get all the benefits of the smaller wheel size, though I suppose keeping pressures low applies to any large volume tyre not just 27.5”/650B. That said, I’m enjoying my time on the new steel prototypes running 29x2.1” and it didn’t take me long to re-adjust to the taller wheels.

GU - You offer Warlock frames from stock but your Vulture Titanium frames are built to order. Do you think you’ll offer a custom fit option for the Vulture?

Tim - Deleting the Di2 routing or adding Anything Cage mounts is something I already offer. Unfortunately, option paralysis exists and often riders have strong views about what they want right up to the point they become indecisive, which doesn’t make for great bikes. I’m of the view that unless you have special fitting requirements, you’re better off choosing a production bike that fits you and has the features you need. A large part of what I do is deciding on a workable balance of options.

GU - There’s some pretty eclectic builds featured on your website. Were the component choices based on what was available, or on personal preference (or a mix of both?)

Tim - What was available, what works, budgetry considerations, plus there’s some marketing as well. I swap parts around between bikes with road and MTB drivetrains and the Gevenalle levers are ideal for that. Also avoiding waste is an issue for me and I has some older bike parts in stock, so I try to reuse them for different projects when I can. A couple of axle spacers and older non-boost MTB cranks make for excellent gravel cranks, with a 47.5mm chainline being ideal for progressive gravel applications, so much so that SRAM offer Wide versions cranksets with that spacing and Shimano went even wider with GRX. I understand it’s hard to look past up-to-the-minute product design, but there are some older components and stuff from smaller brands that work brilliantly.

Also, Fearless sells framesets rather than complete bikes so there’s a likelihood that some customers will want to re-use some of the parts they already own and the examples on the website reflect that. Generally speaking, customers buying a frameset already have a vision of the bike they want. I try not to steer people too much but hopefully the example builds trigger ideas.

GU - Another quick-fire question – 1x or 2x and why?

Tim - I’m a 1x person as I like the simplicity and jumps between sprockets don’t bother me, though this might be because I’m from an MTB & touring background. However, there’s a strong case to be made for 2x and it’s perfect for a lot of people’s riding. A 30T bailout chainring for touring and steeper off-road situations makes a lot of sense.

GU - If you had to sum up a Fearless frame in 3 words, what would it be?

Tim - Fun, versatile, practical.

GU - Finally, what plans do you have for the future direction for Fearless Bikes?

Tim - To keep doing what I’m doing and doing it better.

Thanks so much to Tim for taking the time to talk to us. If you would like to find out more about Fearless Bikes you can check out their website here or follow them on Insta