“One of our customers asked us to custom-build her a cargo bike which she was going to use to carry the pumpkins that she grew on her allotment to a nearby market” As conversation-starters go, this line by Sam from Stayer Cycles, summed up their ethos perfectly. More than ‘just’ frame and wheel builders, Stayer have deep philosophical beliefs and historical reasons for doing what they do.

"We feel like we’re carrying on a long tradition ”

“There’s been a history of bike builders in this part of London since around 1890, so we feel like we’re carrying on a long tradition” said Sam. “If we were to move from here, we would probably move to [nearby] Newham” continued Judith “because they have a really progressive green agenda and are pushing for big social reform changes too”. That in two sentences, seemed to capture the spirit of Stayer – continuing the craft of bike building in their area and having a positive impact on both their local and the wider cycling community seemed to be more important to them than making vast financial gain from their business.

Set up in 2015, Stayer are a frame and wheel building company, but with a social conscience running through the core of the business which sets them apart from their competitors. “One of our aims is to reduce the barriers to a minimum for new riders to get into cycling”said Judith. “It’s why we lend out test frames and test bikes to potential customers so give them as good as possible a first experience of cycling. And at the opposite end of things, it’s also why we were so keen to be involved with the Ultra Distance Scholarship”. She continues “We wanted to share our love of cycling with everyone and help grow diversity within the cycling and endurance-racing communities”

"Having a positive impact is more important than making a huge financial gain"

“Right from the outset, we wanted the business to be sustainable” adds Sam “We decided to have a flat wage structure, to make it as easy as possible for anyone who works here to move between jobs and to have a common goal for everyone. We hope that all of this means we have a positive impact. And that to us is more important than making a huge financial gain”

When I rolled up to Stayer’s east London HQ, the first thing I noticed was a cargo bike sitting outside their workshop. If it had been a swanky 4x4 parked outside instead, it would have given off a very different message, but a well-loved cargo bike and a small collection of Stayer gravel, groad and mountain bikes stacked neatly next to it, told me everything I needed to know about them.

"Workmanlike and understated rather than showy."

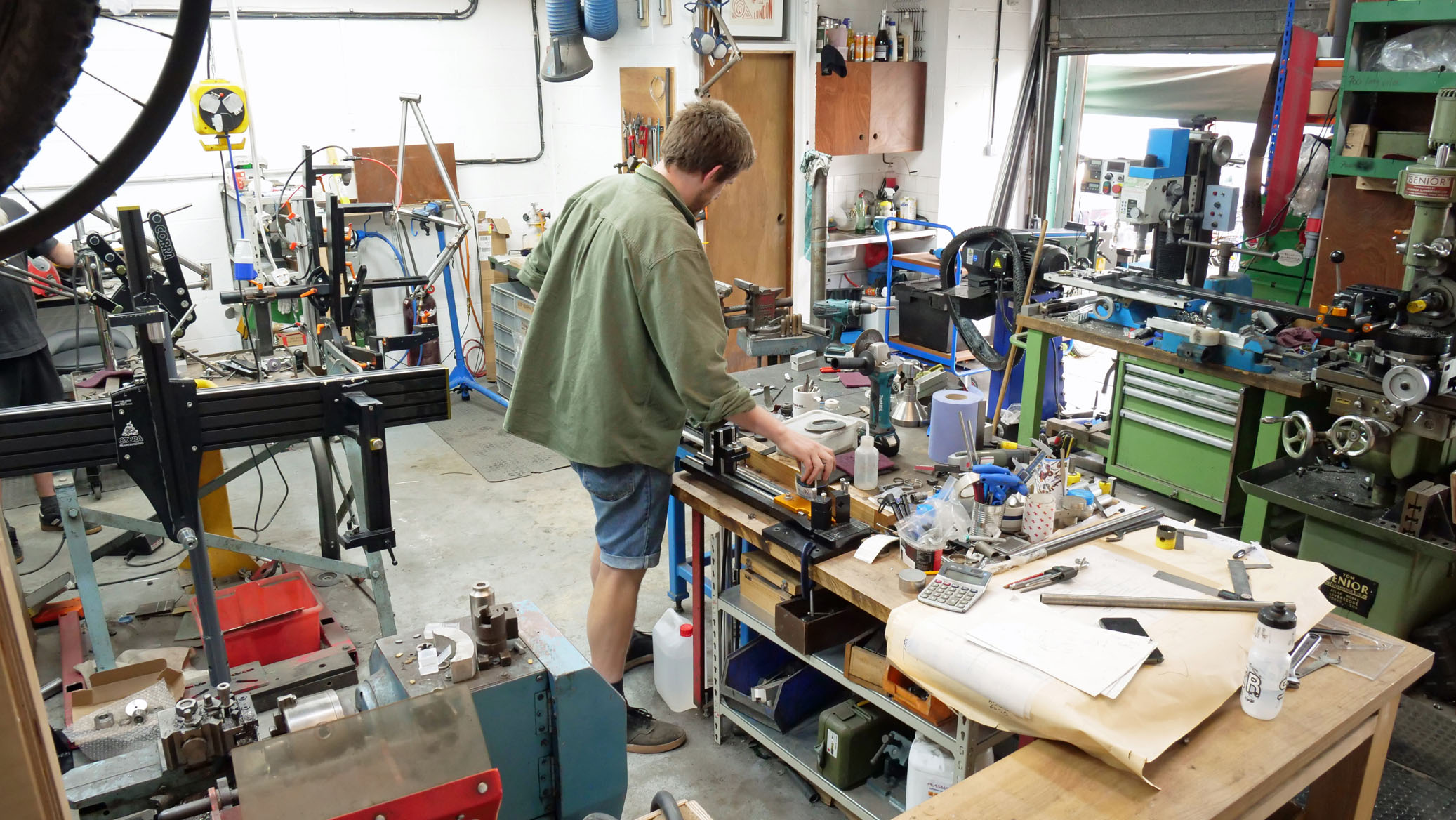

Stayer are based in a small commercial/light industrial estate in East London. They’re not located in a particularly ‘hip’ area and this seemed to fit my impression of them well – they are workmanlike and understated rather than showy. As it was a warm day when I visited, they had fully opened the roller-shutter door at the front giving visitors a view straight onto the shop floor. All the available space was filled to the limit – the ground floor was taken up with a variety of milling machines, welding stations and workbenches.

The back wall had been clad in marine-ply and was hung with finished and partially completed bare frames. Upstairs, a glassed-in mezzanine level was ‘wheel building central’. Again, every inch of room was filled and any space that wasn’t been used for wheel-building stations was used by the team as office space or for orders waiting to be dispatched.

After a guided tour of the world of Stayer, with a freshly poured brew in hand, Sam, Judith and I headed outside to make the most of the warmth and sat down down for a chat about the business. We started off by talking about their history. “There’s a historical precedent in the UK for custom-built road cycling frames” said Sam. “We had some good personal connections with the crit racing scene locally, so initially we focussed on building road and crit frames. At that time, gravel riding was still in its infancy and we needed to push it to get much business, but now it’s gone the other way” he continued.

When I asked about the frame building side of the business Sam told me “We build a mix of full-custom and ‘batch-built’ frames. Full custom is around 5% of the frame business at the minute, but we would like to grow this. Custom-builds are way more labour intensive and can be difficult to price for really unusual requests [like a pumpkin-carrying cargo bike…]. More often, we make tweaks to the fittings and geometry of our off-the-peg designs.” I asked about Stayer’s batch-built designs and Sam replied “With our off-the-peg builds, the frame design and finish is simplified, which makes it much more affordable. By batch-building and then keeping small volumes in stock, availability is better and waiting times are cut, which always helps sales.”

I asked Sam and Judith about the cargo bike that we were sat next to and the frameset I had spotted hung up in the workshop “Cargo bikes fit well with our green agenda” said Judith “but due to their size, parking & storage is an issue and this affects how many we can sell. We’ve been talking to the local council about running a rental scheme and the possibility of them putting in secure on-street parking, but this is still quite a way off. The cargo bike market still needs some stimulation [on a national level] to help it grow”. If you do fancy a cargo bike to transport enormous home-grown veg to market, or for any other reason, you know where to find them.

"During the Covid19 pandemic, demand for gravel bikes exploded."

Getting back on track Sam explained what had happened to the business during the Covid19 pandemic “We had much less demand for road race/crit frames during this time as the race scene was so reduced, but the flip side is that demand for gravel bikes exploded”. “Gravel bikes fit really well with our ethos” he continued “as they’re all about riding straight from your door, they’re perceived as being more accessible and probably safer too, as you’re riding away from the traffic. We love riding gravel bikes ourselves as they offer us the combination of fun and freedom that we’ve craved over the recent period.

During the first three months of the CV19 pandemic we received a year’s worth of orders, which was great in some ways, but also problematic in others. There was a huge shortage of bottled oxygen [which is needed as part of the brazing and soldering process] as medical demand increased so dramatically. Then there were difficulties getting enough supplies of welding rods. Now things have changed again and its components that are hard to source. We had plans in place for offering more full builds and also new wheel offerings, but supply issues have been a big problem”

Judith, who is charge of the wheel-building part of Stayer, explained how things worked “Initially wheel builds were the biggest part of the business, but slowly this has switched and wheel sales now make up about 40% of what we do”. She continued “Our first offerings were all 650b as this size of wheel offered the ideal combination of high volume tyre size while still being manoeuvrable and also compatible with a wider size of frames, particularly smaller ones. Now though we make 700c/29” wheels too.

All our wheels are hand-built, with most made to order, but we do keep a small stock of ‘ready to roll’ wheelsets too. We build everything from fixed gear track/crit wheels, to lightweight road wheels to expedition off-road wheels with a dynamo front hub. We really focus on attention to detail. For example, we cut and thread all our own spokes, so that we can get exactly the length we need. It’s not one size fits all with wheels, as everyone uses them differently, so we will build it for what you’re going to use it for”

We moved from chatting about Stayer wheels back to their range of frames and bikes. “We started with the Groadinger UG or Ultra-Grav” said Sam “This is a traditional gravel bike. It’s lightweight and comfy and is perfect for big distance bikepacking. It’s perfect for gravel riding or road riding and has a really planted feel. It will take 650b or 700c wheels, with space for tyres up to 40c”

“Then we have the OG and OG+ We like to think of this model as the manoeuvrable tractor in the range. A Speedway Massey-Ferguson if you will. It’s a short wheelbase dropbar drop bar trail bike and is just as happy smashing it around the woods as it is being used on a long distance offroad bikepacking trip. The OG is designed for 650b wheels and the OG+ is the 29er model and will take tyres up to 2.4” width” he continued.

“Last but not least we have the OMG” Sam went on “This is the perfect gravel bike for mountain bikers and is a short wheelbase dropbar hardtail, with clearance for 29x3” tyres. We think of it as an extreme bikepacking rig, but as all of these are custom built at the minute, we can make it whatever you want it to be. We are planning on offering small numbers of these as a batch-build in the future, but we’re not quite ready yet.”

Stayer also have a range of custom offerings – the All Road and the Crit Bike being their most popular, but they offer Full Custom too, if you fancy something more esoteric.

"The speedway Massey-Ferguson of the gravel world."

Something that I felt ran through the heart of what Stayer do was a strong desire to do things ‘properly’ and to not make the business just about creating profit. There was an element of Victorian-era cooperative about it, which also fitted nicely with the history of Victorian bike builders in the area. Sam and Judith were super keen to treat everyone the right way – whether it was customers, staff or the wider cycling community. “The quality of our product is key. It would make more financial sense to outsource what we do, but it’s integral to the business to make the stuff ourselves and to do it properly. Ultimately, giving our customers a positive experience is the key to our success” said Judith.

“We’ve made a big investment in bikes that people can try” said Sam “There’s no substitute for actually trying a bike. But this doesn’t just apply to paying customers – for the Sisters in the Wild event this year, we loaned out two of our gravel bikes, gave away two entries and provided two sets of camping gear, so that women who had never had the chance to try bikepacking before were able to try it for themselves. It’s all about us doing our bit to help reduce the barriers to entry.”

Stayer are also one of the key sponsors of the Ultra-distance Scholarship – a project set up to “elevate representation in the discipline of Ultra Distance racing and to amplify conversations around the lack of diversity in the cycling world at large and hopefully inspire others in the industry to take initiative.” For 2022, the Scholarship provides three riders from BAME backgrounds with a Stayer bike, coaching from a performance coach, mentorship from a top-level ultra-racer and a variety of kit from Wizard Works, Albion, Outdoor Provisions and Wahoo. The aim for the Scholarship is for the riders to take part in the 2022 GBDuro event, so they have also been given a guaranteed place in the event.

As we rounded off our chat, I asked Sam and Judith what their plans were for the future. “Because we make everything in-house, including doing our own R&D, our timescales are quite long, but investment in the business is worth it (and necessary) to make sure everything we make works properly and is reliable” said Sam. “We want to continue what we do, but with more customisation of our products and where we can a lower price point to make our sport more accessible” added Judith.

“We are going to continue to invest steadily in the business so that we can hopefully double our frame output and also grow the wheel building part of the business to 50% of what we do” said Sam. Judith chippe in here “We’re going to be adding aluminium wheels to our range”. “And most importantly” continued Sam “We want to continue investing in great training for our staff. We’re only a small team, so proper training and investing equally in everyone is vital for the business.”

That seemed like the perfect summary of Stayer Cycles – no big plans for world domination or flashy product launches, but an aim to invest in the business, grow steadily, keep quality their top priority and to treat their staff decently.

If you would like to find out more about Stayer Cycles, check out their website here.