“If it was easy, everyone would be doing it”

“If it was easy, everyone would be doing it” is hand written on a white board on the back of the door leading out of Viola Townsend’s diminutive workshop. I had this phrase in mind as I later held an example of one of her custom-made carbon fibre tubes in one hand and my camera in the other, trying desperately to capture a telescope-esque view of the lighthouse on the far side of the River Tyne. Passers-by were giving us slightly strange looks. “Why the hell is that guy holding a piece of black tube up to the sky?” was probably what was going through their minds.

But Viola, a.k.a Sideways Bikes , is not phased by the thought of raising a few people’s eyebrows. A relative newcomer to the framebuilding world, Viola, who trained as a mechanical engineer and who has nearly a decade of experience of working with composites gained in the aerospace/motorsport/fishing rod industries, gained some major exposure to the bike world when she first won the “Bespoked x SRAM” inclusivity scholarship to attend Bespoked in 2022 and then went on to win the 2022 award for Best Off-Road bike.

“I know I genetically inherited cycling from my Grandad and maybe some of the chemical stuff too”

“My grandad was sort of my drive towards cycling” said Viola, when I asked her how she first got interested in cycling. “He was originally a chemical engineer. He's got a patent for a carbon fibre making machine from the late 1960s, when the UK was still at the forefront of carbon fibre production. I know I genetically inherited cycling from him and maybe some of the chemical stuff too” she went on.

"I also really wanted to learn about how it all worked and just sort of see what makes up a carbon frameset"

As Viola gives me a tour of her workshop, she tells me how she first got interested in cycling and how this eventually led to her setting up Sideways Bikes. “When I went to Uni, I suddenly had a lot more free time and some actual money to spend on bikes. Basically, my first few student finances were spent on bike bits. I decided I wanted to try and get under seven kilos for as cheap as possible with a carbon frame. I bought a Scott frame and took all the paint off. I really wanted to learn about how it all worked and just sort of see what makes up a carbon frameset. I've since bought lots of others, most of which I've cut in half “ she continued “but I really don't want to touch the Scott because I think it looks awesome. It's interesting to see the construction and to learn where filler is used, even on a high-end frame built with a big budget.”

"It kept cracking and shattering "

Viola continued to talk about her route into carbon frame manufacturing “Unfortunately, at my Uni there wasn’t a cycling society, so without being able to find much bike stuff, I went into Formula Student instead, where we made a single seater racing car. I learned a huge amount from the technicians who helped out in there and who did machining for projects and pointed the students in the right direction when we got stuck on something. The Formula Student team didn't really have much composites except for a kind of fibreglass seat, which they'd used the knowledge from the art department to make. It kept cracking and shattering and I decided I wanted to try and make a carbon fibre seat for them. So, in my second year that's what I did.”

"I think it's really good to be able to look back and go, ‘Look how far I've come’ "

I asked Viola how she progressed from motorsport to bikes. “I developed a kind of obsession with composites and from there grew my love of making lightweight bikes. For my dissertation, I really wanted to build a carbon fibre bike or do something with composites, but I really desperately didn’t want to do it on the Formula Student car. So, I went to the Materials Science lecturer and said ‘Would you be down if I did this?’ He said OK, but I had to agree to do some testing on coupons of carbon as part of the thesis, which I duly did, but I also built a bike. I look back on it now and think, Oh, this is terrible. But it's I think it's really good to be able to look back and go, ‘Look how far I've come’”

Viola continued “For my thesis frame, I bought the tubes of the main triangle and the tubes for the seatstays, because this was all done under Uni time pressure. I made the chainstays and then made the lugs that joined the tubes together. This was the beginning of experimenting with things. I tried to make handmade bladders where you get two sheets of plastic and stick them together. They would frequently burst or not conform or spring a little leak. I tried vacuum bagging over an internal mandrel and pulling it off, but often you couldn't get it out, the corners would be terrible and obviously the outer finish wasn't good. “

“And then, once I'd managed to figure out something that worked on the front part of the frame, then I had to move onto the rears which become three-part moulds. So that added complexity as well. With time crunch off of it all, it was a bit hectic. But I got it done in the end and the finished frame is about 850 grams or so. It's never been officially strength tested. I've ridden it a fair bit, but it hasn’t passed any proper tests. The main issue was that the bottom bracket shell wasn't particularly round, so it started creaking really quickly, but all in all I was pretty happy with it. “

"I set my sights on learning everything I could about composites from all the different composites industries"

I asked her next about her career progression – how did she get from being a student engineer to where she is today as an award-winning custom frame builder? “When I graduated Uni, I set my sights on learning everything I could about composites from all the different composites industries. I then had a bit of a tumultuous couple of years bumping around different places. I did everything from helping produce composite molds for Formula1 cars, to making carbon fibre bath tubs to making arm rest extension bars for time trial bikes”.

At this point in our conversation, Viola wheeled out a skinny framed, calliper braked road bike, painted in Barbie pink. It has the classic good looks of a traditional, old skool race bike, but when you look more closely, you realise that the frame is made of carbon, not steel as you might have first thought, when looking from a distance.

Image courtesy of Bespoked

"This bike is really me and captures exactly the type of bike I wanted to ride”

Viola talked about the story behind the bike “Last year, I decided I wanted to do that first frame again, but with five years of experience under my belt. It was one of the things that I showed at Bespoked. You can see the progression from the first frame. It's almost exactly the same geometry, just with a slightly shorter head tube and slightly bigger chainstays. I made every single tube myself, made all of the lugs myself and just made them way better. I put in a big chunky metal button bracket, which adds 100 grams of weight but means you get a better fit and no creaking and all the rest. Then I painted it in these horribly garish colours to make it stand out.”

“I felt a little out of place with a bike like this, particularly when gravel was just so ludicrously popular”

It was really obvious how much she loved this bike and how much building it meant to her and encapsulated her riding style “This bike is really me and captures exactly the type of bike I wanted to ride. I really wanted to make sure I had it to bring to Bespoked. I felt a little out of place with a bike like this, particularly when gravel was just so ludicrously popular. Annoyingly, my paint was really bad – it came out powdery and awful. I'm not a fan of the colour replication - I bought one colour expecting something else. I did this because, although I don't really like waving a flag about my gender identity, I wanted it to stand out. “

"It’s really nice coming to the bike industry to find that a larger amount of people are just nicer human beings really.”

We talked next about diversity and inclusivity in the cycling world. “As part of the Bespoked inclusivity scholarship, they wanted me to talk about the sort of challenges I have faced in the bike industry, to get where I am. I've not been like neck deep in the bike industry for all that long because I've just been in the composites industry, so I think I can talk more about that. But a lot of what I found in composites, in engineering in general, is just horrendously bad masculinity and sort of politics. It’s really nice coming to the bike industry to find that a larger amount of people are just nicer human beings really.”

"The guests at the show must have been so confused when they tapped this, expecting steel, but only to find out that it’s carbon."

We chatted next about how she’d found the experience of being an exhibitor at Bespoked as a relatively new frame builder? “Something I learned at Bespoked is that apparently a lot of the old boys and will be seen tapping the tubes on the steel bikes to try and tell if and where the steel tubes are butted and loads of people were coming by, tapping this frame. To me, tapping it is to see how much you can tell about the carbon construction. The guests at the show must have been so confused when they tapped this, expecting steel, but only to find out that it’s carbon”.

Now that we’d established Viola’s path from student to professional frame builder, we moved on to discussing her gravel bikes. You might ask why it took so long to get there, but her road cycling heritage is a big part of the bikes she loves to build. “Gravel bikes open up so much potential riding and it's fun to explore new trails, but I always want to make sure I have my roots in mind. I quite enjoy the idea of being under-biked for a situation and think it's I think it helps train in some good skills to the rider."

“This bike was encouraging me to go down the canal path and go through the parks”

She continued “I've always wanted to ride in a cyclocross season. But when I was at Uni I couldn't do it because I couldn't get to any of the races because I didn’t have access to a car. Then when I moved up here and wanted to do more of it, I haven't been able to because of time either. At Uni I had a second-hand steel framed single speed bike, that I set up with used cyclocross tyres that I used to get off eBay. I started riding that with drop bars on and just quite enjoyed finding places to go and get sort of stupid with it. When I was riding into my little part-time job, this bike was encouraging me to go down the canal path and go through the parks and deliberately ride over this muddy, rutted bit of grass, rather than going on the road”.

“This was only sort of five or six years ago, but I was struggling to get anything more than the 32mm tyres that didn't feel like concrete to ride on. The tyre clearance was a nightmare, toe clearance got weird and the geometry was just a bit too steep for tackling some of the trails that I found. I decided at this point to get a bit more gravelly and to build myself a gravel frameset. I put moustache bars on it and it's quite fun to just cruise around on. I quite enjoy the options it opens up to me. Being under-biked is one thing, but having a bit more bike to tackle things is nicer because it means I can be well-biked for a lot of the trails around here and go and find the ones which I'll be under-biked for too. “

“I'm improving all the time”

At this point in our conversation, we turn our attention to Viola’s award-winning gravel bike. There are all sorts of really cool little details that I hadn't appreciated when I saw the images of the frame, such as the impressive shaping on the top tube. I asked her how she achieved this on a handmade tube.

“That's my favourite tube on the whole bike but was really challenging to build” she told me “I have the ability to design whatever tube shape I want and I can choose to “butt it” differently [although carbon tube profiles are not the same as traditionally butted steel tubing]. This frame is actually lacking a bit in finish qualities. I think I could have been a lot smoother. But I'm getting there now. I'm improving all the time and that's why I haven't put out a frame in the last two months or so, because I've wanted to get everything absolutely perfect.”

“This gravel bike and the prototype build before it look very similar and have the same tube shapes, but I play completely different games with the interior lay up of them. The curse is that sometimes I can get things wrong and things can cause an enormous headache for me. The drop chainstays I thought it'd be a really cool idea for example, but they really were a complete nightmare to work around.“

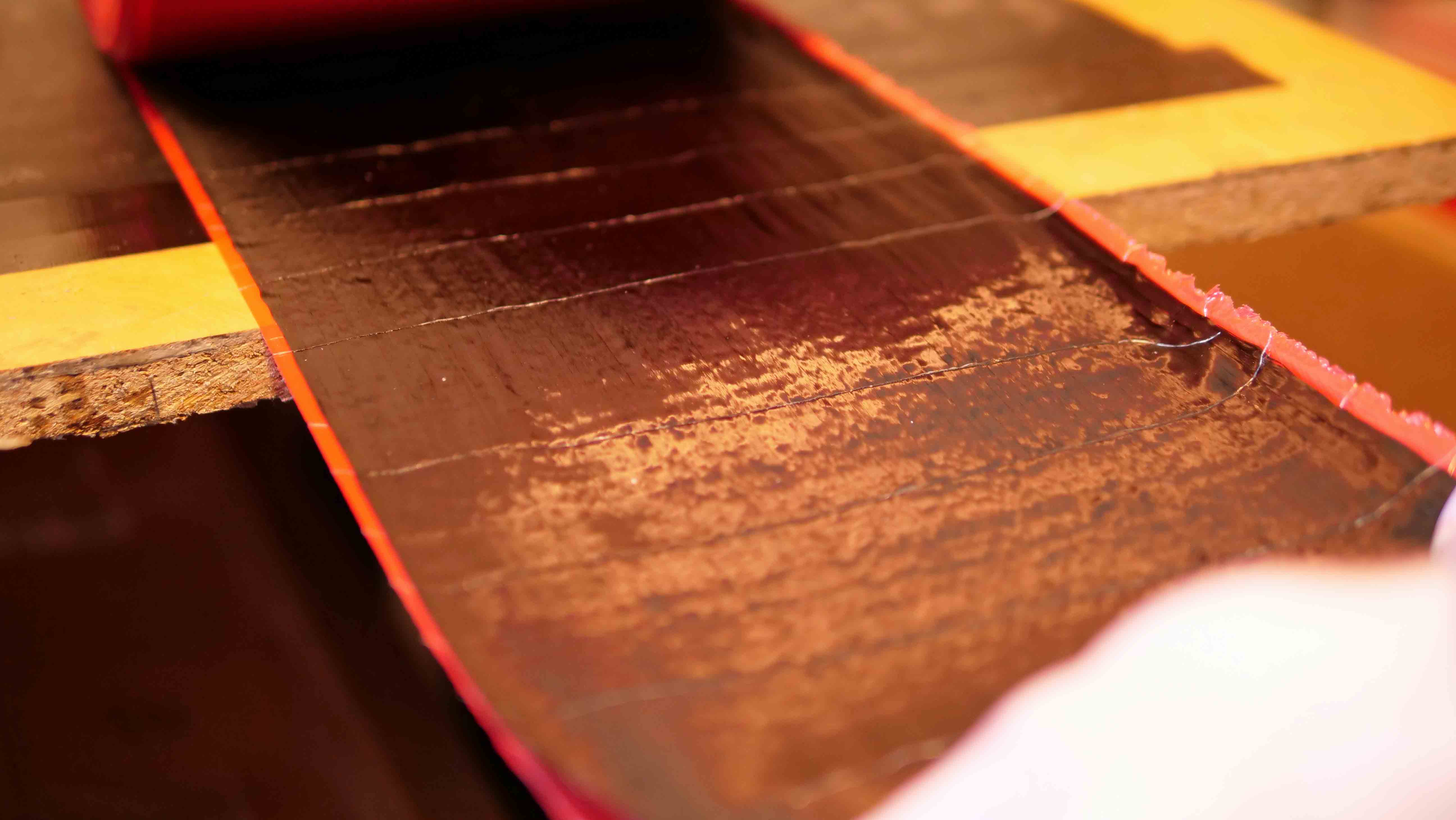

At this point Viola and I started to talk about the actual carbon layup process itself. She was incredibly open about the process she uses, the fact that she had been forced to design and build (often using a 3D printer) the jigs and tools that she needed for the tube manufacturer process and how she sourced her raw carbon fibre. But she also admitted that she was slightly wary about giving away too many of her hard-won techniques and methodologies. I was amazed at how the process of turning raw carbon fibre sheets into finished tubes and parts was both really complicated, yet also quite rudimentary. She was incredibly generous in letting me use the images of some of her workshop set-up, but asked that I didn’t divulge too many of the specifics of the process. Suffice to say, Viola is constantly on the search for better, more efficient processes and her future frames should be well on the road (or should that be trail?) to matching the look and quality of anything that bigger manufacturers can produce.

"Sometimes when I can't sleep, I just sit up designing new frames and just playing around with new ideas."

We finished off by talking about the future. “I love to design my own things. I've probably got ADHD or something, but I've got a million different ideas of things that I want to do. Sometimes when I can't sleep, I just sit up designing new frames and just playing around with new ideas. I was playing yesterday with some ludicrously short chainstays and ridiculously dropped seatstays. None of these are likely to ever get built, but I love experimenting.”

“Mainly, I‘d just like to keep building frames that are fun to ride. I want to build frames for customers that have a reason for them to be custom. Whether its related to your fit metrics or because you have some funky ideas that you want to see or whether you just want something visually a bit striking and you want to make that happen. I’d like it all to be really unique.”

“I don't want to be stuck doing the same thing and that's the whole reason I started doing this. In five years’ time, I would like to be building a frame or so a month and having the time to focus on doing it properly, not just trying to capitalise and make big money out of it. I just really sincerely enjoy building bikes and that's what I want it to be. I just want to happily enjoy making the best. That would be where I'd actually love to be.”

You can find out more about Viola’s custom carbon fibre frames here